- Mixer Series

- Screen Printer Series

- Printing peripheral equipment

- Printing consumables

- Machine accessories

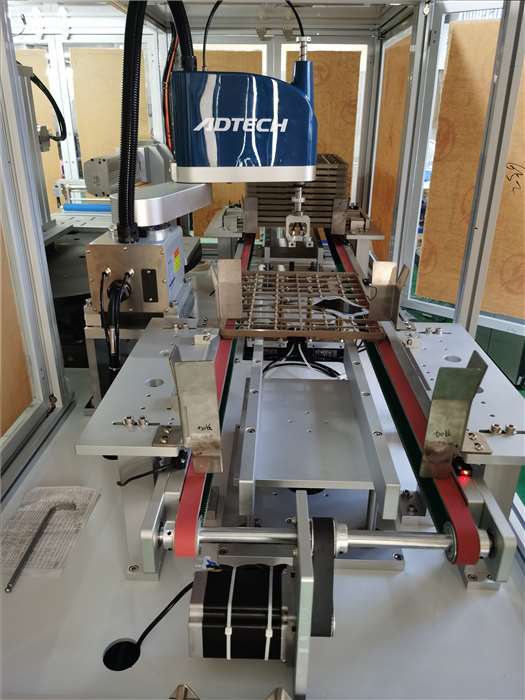

- Fully automatic screen printer

- Fully automatic transfer press

This is a high-speed and high-precision rotary screen printer. It uses Taiwan mechanical cam divider to form a high-speed rotary table, which is balanced and stable when rotating at high speed and has little vibration. At the same time, the workpiece can be taken and placed to improve production efficiency. The fastest speed can reach 2000 printing times per hour. It is your preferred model for mass printing. At the same time, according to product requirements, automatic feeding and unloading system can be installed to save labor, improve production efficiency and realize printing automation.

Performance description:

1. Imported PLC compiles action program, fully numerical control operation, to achieve the digitalization, standardization and humanization of work

2. Imported high-precision ball screw and imported servo motor constitute lifting structure, which has fast speed and high precision.

4. Adjustable left and right travel, Taiwanese photoelectric switch limit

5. The angle of scraper/ink returning knife can be adjusted arbitrarily.

7. The position of the net frame can be adjusted from front to back, from left to right, from horizontal to high.

8. Inspiration positioning system, accurate fixed product printing

9. Driving mode: All imported servo drive from top to bottom to improve production efficiency and printing accuracy

10. Rotary table workstation: 2, 4, 8 arbitrary choice

technical parameter

Maximum printing area: 200*300 mm

Left and right journey: 500mm

Up and down journey: 150 mm

Disc diameter: 600 mm

Maximum height of workpiece: 80mm

Printing speed: 2000 prints per hour-

Size: 1000*1150*1670mm

Rotary table workstation: 2, 4 and 8 workstations (selected according to product size)

Scope of application

Precision screen printing of paper, stationery, glass, plastics, hardware, non-adhesive, single, double, multi-layer circuit (PCB), liquid green, cold light film (EL) and flexible circuit board.