- Mixer Series

- Screen Printer Series

- Printing peripheral equipment

- Printing consumables

- Machine accessories

- Fully automatic screen printer

- Fully automatic transfer press

First, the printing press has the following characteristics:

1. Servo motor is used for screen lifting, which combines with high-performance guide screw and precision linear guide. Screen frame lifting is guided by screw, printing is smoother and smoother, and printing accuracy is higher.

2. Stepping motor is used in printing frame, which runs fast, locates accurately and sets the travel/speed/direction digitally.

3. The printing frame is formed by pulling aluminium in one, and its structure is simple. The tool holder is guided by cylinder with cross roller guide, which is stable and smooth with high precision. The scraper and ink knife are formed by pulling aluminium in one. The structure is simple, the use is convenient and the performance is stable.

4. The rotary table is driven by Taiwan precision cam divider. The repetitive positioning is accurate and fast. The micrometer of the table is fine-tuned (stroke (+6mm), the vacuum suction table is precise, and the product positioning is precise, so as to prevent the product from loosening in the process of rotation. The turntable is made of cast aluminium with stable structure, superior rigidity and 0.05 mm flatness accuracy.

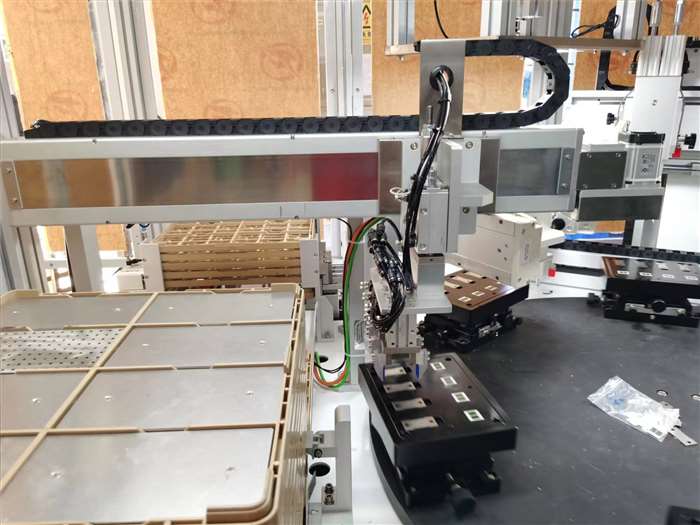

5. Manipulator blanking: Configurable manipulator blanking, reduce productivity, improve production efficiency, machine and production line docking, directly to the production line, can be customized according to customer requirements.

6. Using advanced control Mitsubishi PLC control and human-machine interface digital control, it can set a variety of functions and operating parameters, which is conducive to the digitization and standardization of operation and humanization.

7. Install safety rod, safety screen, and protect operator's personal safety carefully.

8. Oil-free water filter pressure regulating unit does not produce oil mist pollution, and is suitable for dust-free indoor use.

9. The function program sets the storage function and keeps it in mind for the convenience of next use.

Technical parameters:

1. Printing colour 1 colour (multi-colour)

2. One cycle may

3. Continuous exercise can

4. Item counting can

5. The delay of each part can be adjusted.

6. Printing speed 1200 times per hour

7. Maximum mesh frame 400mm X650mm

8. Maximum printing area 180mm X250mm

9. Workbench size 200 mm X300 mm

10. Diameter of turntable 845 mm

11. Working Number 4

12. Robot Travel 500 mm

13. Maximum height of workpiece 80 mm

14. 200 mm landing distance on net frame

15. The left and right stroke of the scraper is 350 mm.

16. Scraper and oil scraper travel up and down 30mm

17. Vertical and transverse adjustment of worktable (+6 mm)

18. Vacuum adsorption or finger clamping

19. Lift Drive Servo Motor

20. Control System PLC

21. Control Voltage DC24V

22. Power supply voltage AC220V 50/60Hz

23. Connection load 2.2KW

24. Working Pressure Mpa 0.4-0.6 Mpa

25. Air Consumption/Cycle 3.0L

26. Fuselage dimensions 1160 mm (L)*1450 mm (W)*1600 mm (H)

27. Weight 560 KG

3. Safety performance of machine operation:

RH-2030p precision rotary screen printer conforms to the latest engineering model, if used as required, it is absolutely trustworthy. The machine is equipped with emergency switch: when pressing the emergency switch in case of an emergency, the machine will be cut off immediately. Back to the starting position, when things are handled, the emergency switch is twisted out, and the safe start can be restored to normal.

Notes:

(1) When the machine needs to be moved or repaired, the power and air must be cut off.

(2) When adjusting or cleaning the oil scraper, please follow the steps.

(3) Strengthen fire prevention awareness and equip fire fighting equipment.